Tool drives

Versatile

The PFERD TOOLS range includes tool drives for grinding, milling, brushing, cutting and polishing in manual applications as well as in robotic and semi-stationary applications. PFERD TOOLS is one of only a few manufacturers that can offer a range of tools for work on surfaces and cutting of materials, as well as drives designed specifically for these tools, all from a single source.

The wide product range includes air and electric grinders as well as DIN 10 / DIN 15 drive systems, and thus offers the best solution for almost any working environment.

PFERD TOOLS tool drives are characterized by their performance and durability. They are less prone to faults and comply with the latest technological standards.

Maintenance and repair service

PFERD TOOLS provides a maintenance and repair service, which includes basic cleaning, repair and final safety checks at our factory. Our qualified specialists will be happy to draw up a detailed, no-obligation quotation without delay.

If a repair doesn’t make financial sense against the cost of a new machine, you will also receive a quotation for a new tool drive. Only genuine PFERD TOOLS spare parts are used to repair tool drives. After the repair, your tool drive will be returned in an as-new condition.

An experienced team ensures that repairs are carried out quickly at the Marienheide plant in Germany. Please send any queries to pferd.power.tools@pferd.com .

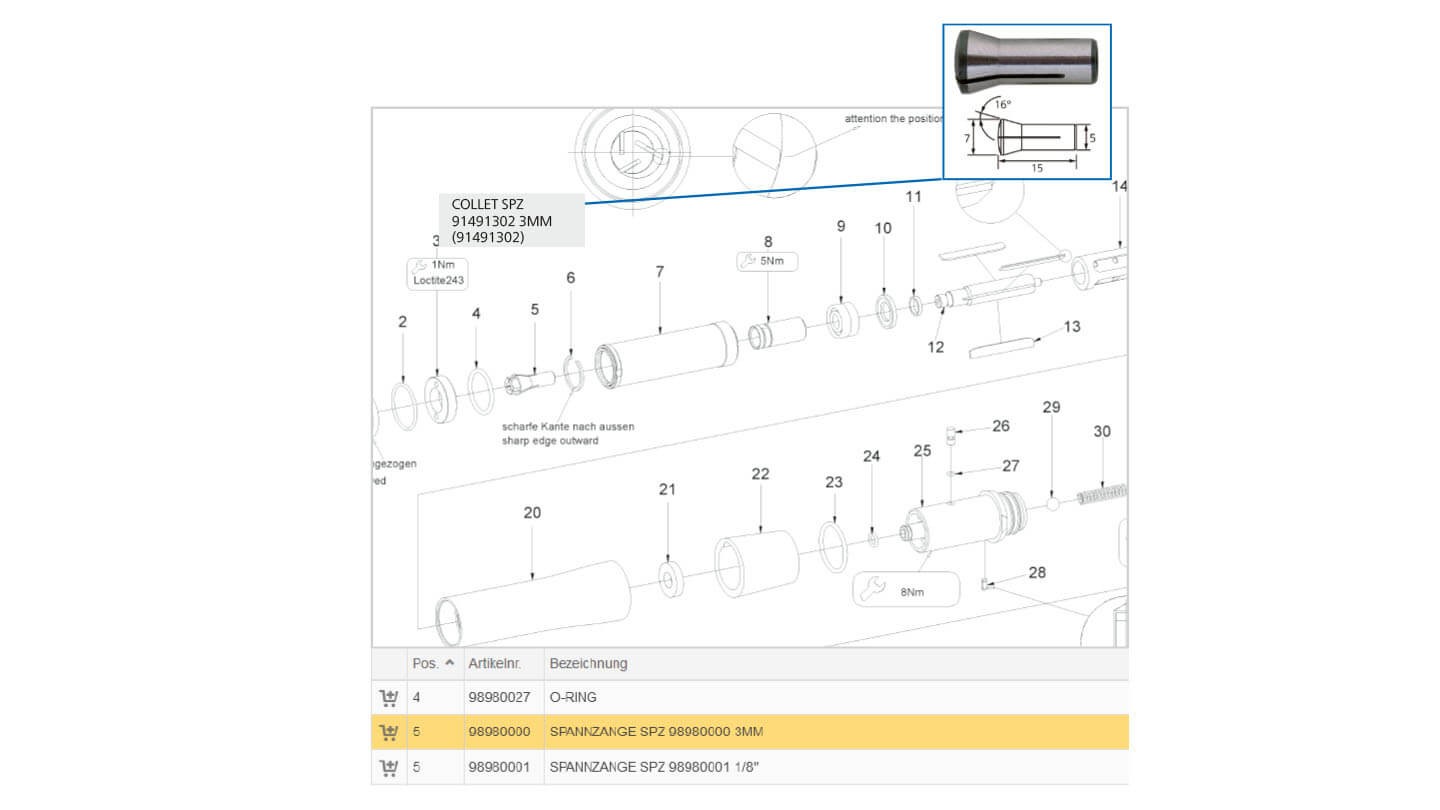

Spare parts catalogue

The machines can be serviced by us, or in some cases you can also repair them yourself. We have put together a separate spare parts catalogue for you to ensure you can find the spare parts you need. It not only contains exploded drawings listing all spare parts, you can also download safety instructions.

Safety notes

Please read the operating instructions and associated safety notes. In accordance with the legal requirements, all tool drives are accompanied by operating instructions containing a CE declaration of conformity, and safety notes.

Cost-effectiveness

The faster the grinding process, the more cost-effective it is. If you need to determine the correct rotational speed, simply use our rotational speed calculator.