Non-woven material as an abrasive

The perfect finish with non-woven abrasive materials

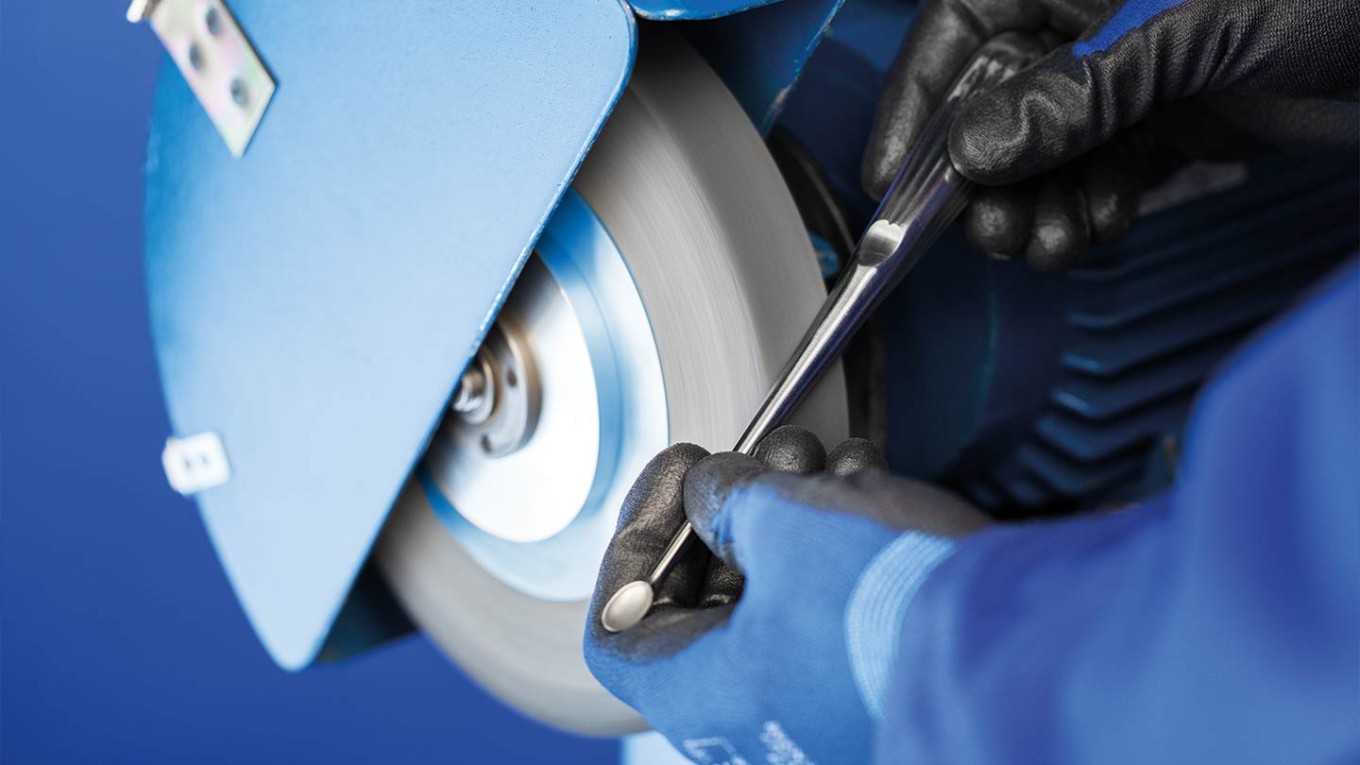

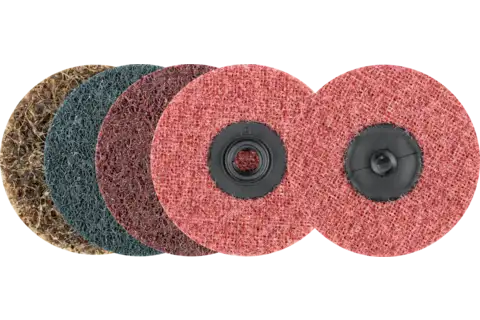

Non-woven abrasives come into their own where other grinding tools reach their limits and are unable to produce the desired results. Non-woven abrasive is one of the most flexible abrasive materials and is suitable for manufacturing a range of different tools such as hand pads, grinding drums, discs, belts, round plates, wheels and grinding points.

The abrasive properties of these tools are adapted to different applications and provide an excellent solution for many applications when working on the surfaces of numerous materials. The elastic properties of the polyamide fibres together with the higher-quality sharp abrasive grain give rise to outstanding, gentle finishing tools.

Even stock removal rate thanks to three-dimensional structure

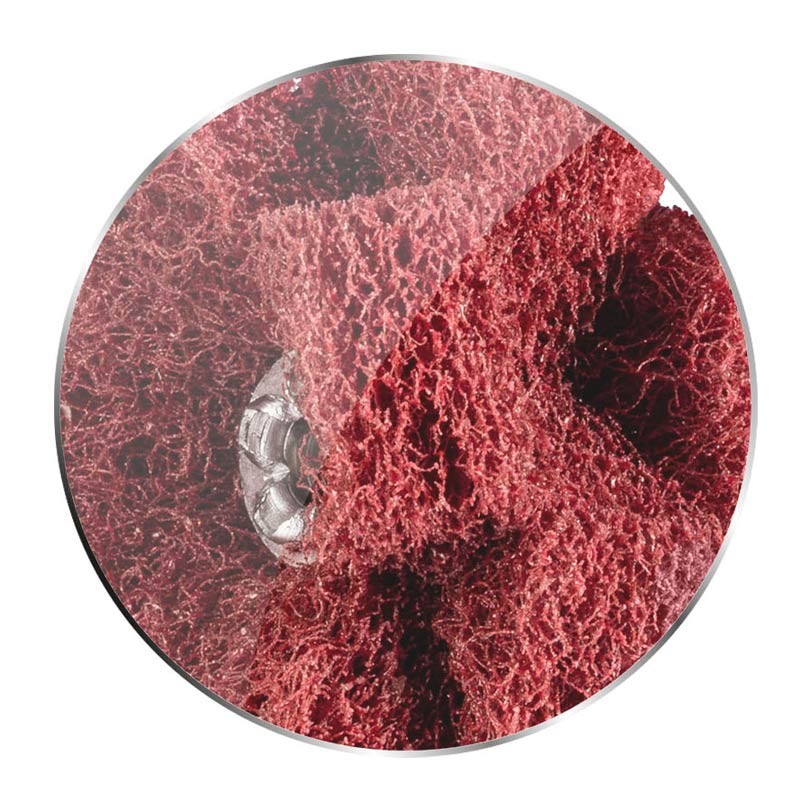

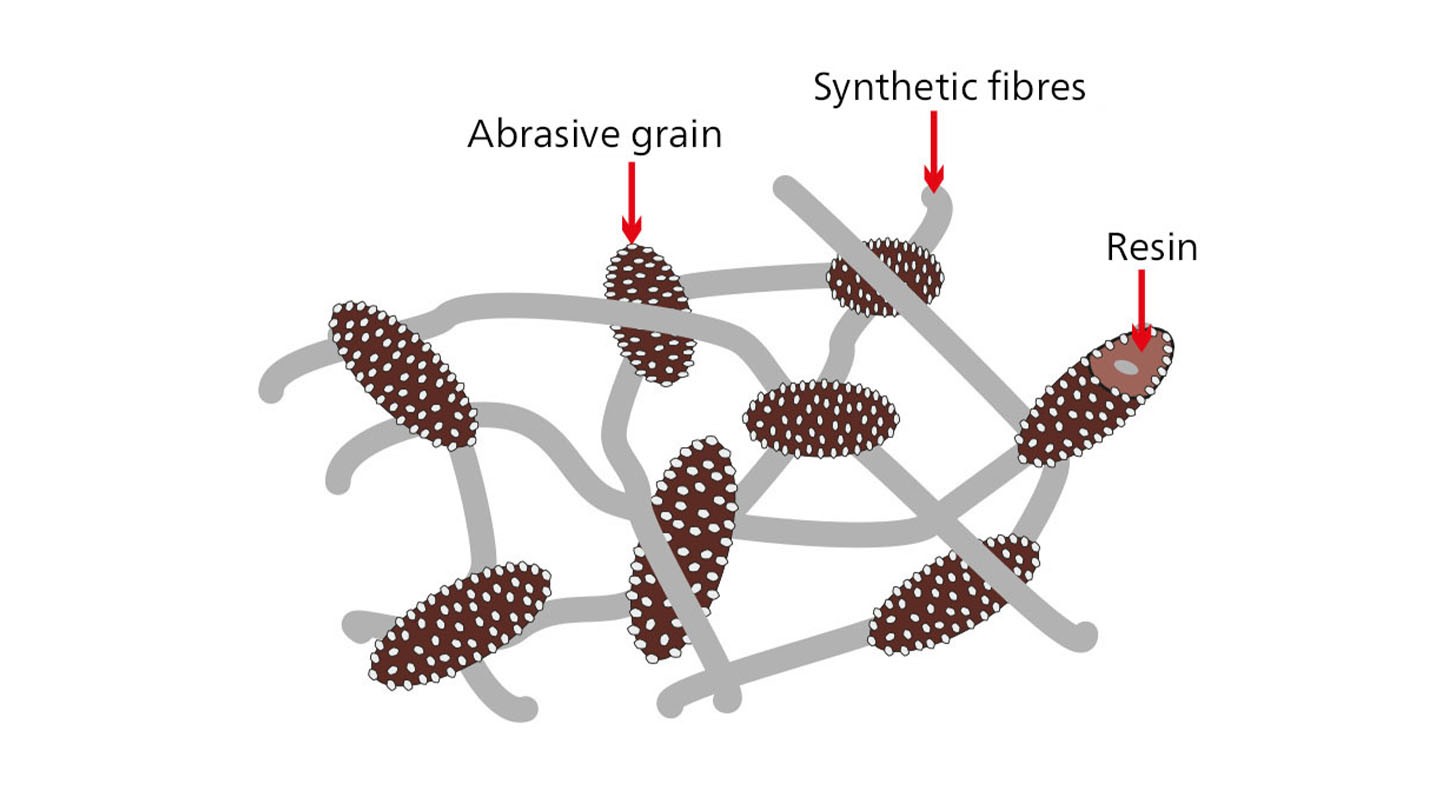

Non-woven abrasive has a three-dimensional structure consisting of polyamide fibres, synthetic resin and abrasive grain. The non-woven fibre structure is impregnated/interspersed with resin and abrasive grain. The even distribution of the abrasive grain within the non-woven mixture guarantees a continuous supply of fresh, sharp abrasive grain during the entire grinding operation.

Unique satin-finished grinding result

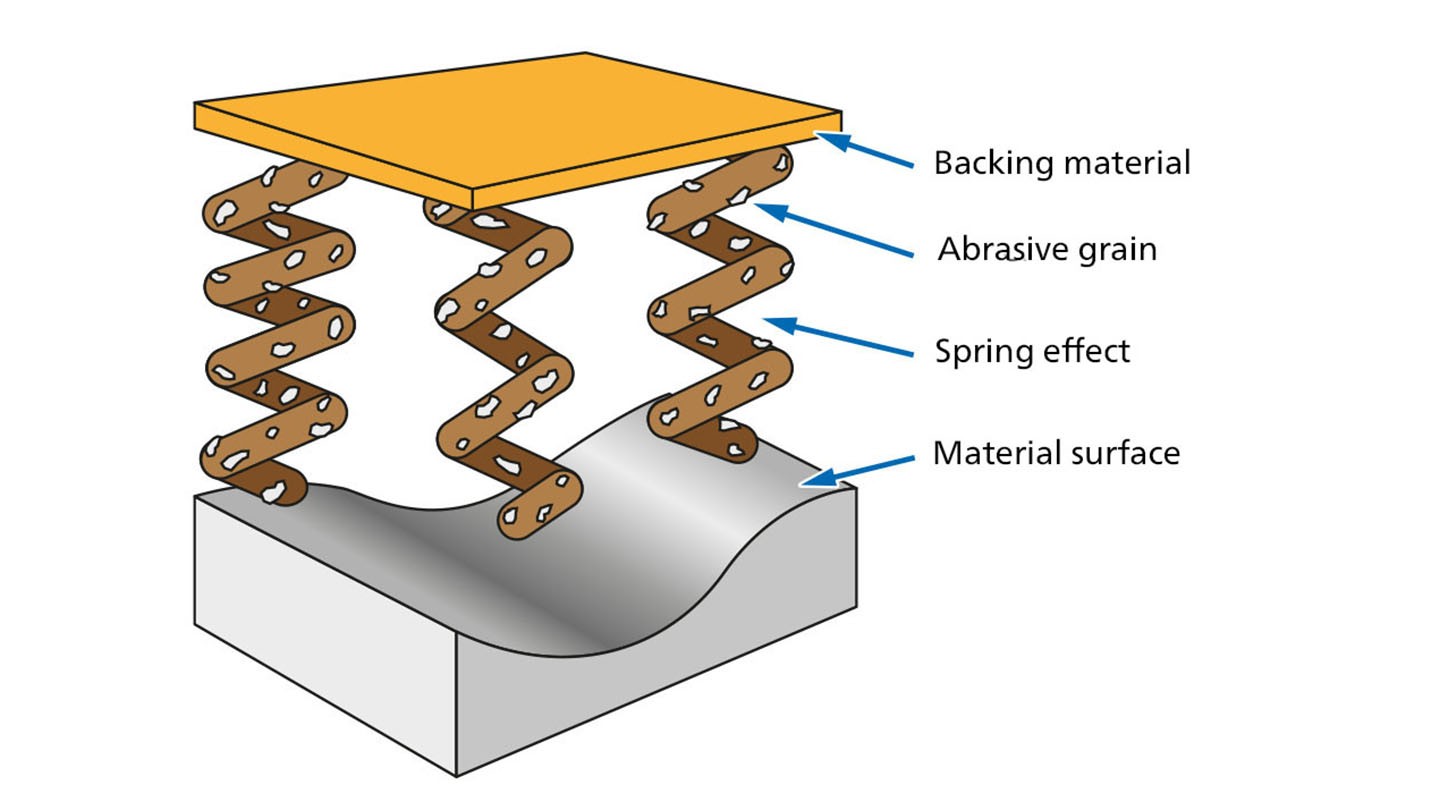

The very loose connections between the individual fibres ensures a high level of flexibility and gives a strong spring-type effect to the non-woven material. It is flexible and supple, and leaves behind a very distinctive surface structure. The satin-finished grinding result is unique and cannot be achieved with other abrasives.

Different structure, same abrasive

Even though non-woven abrasive has a completely different structure to flexible coated abrasives, the same abrasive materials are used for both tool groups:

- Aluminium oxide (Al₂O₃) is very durable, achieves a top tool life and is very aggressive on hardened steel. The surface generated is characterized by a higher level of shine. When used on aluminium, discolouration is prevented.

- Silicon carbide (SiC) is even sharper, harder and has better cutting characteristics. It quickly produces a finer, long-lasting slightly matte grinding pattern on the surfaces of many materials.

Selecting the right grit size

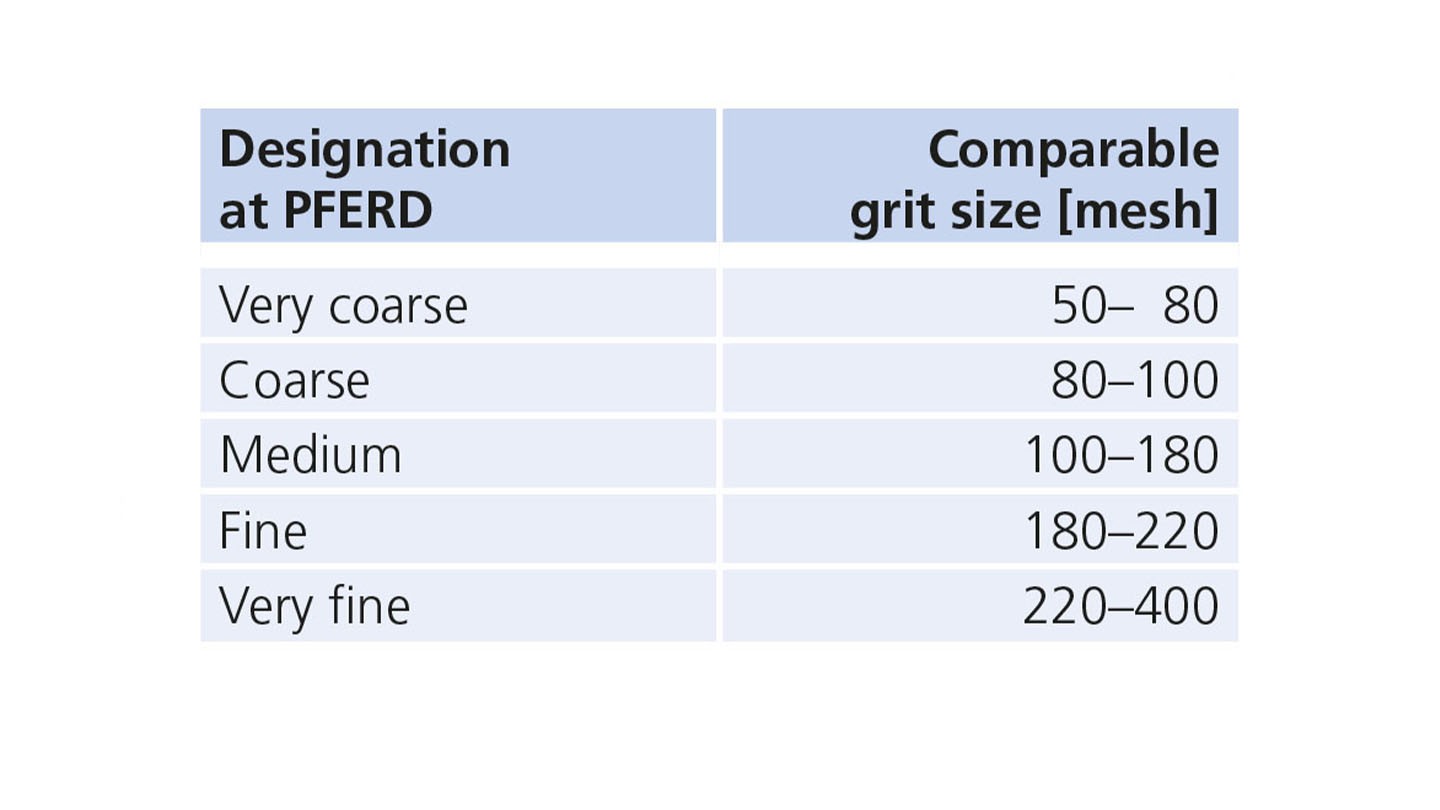

With conventionally bonded abrasives or coated abrasives, the user selects a specific grit size. Non-woven abrasives are labelled according to the following scheme:

The abrasive of choice for different industries

Non-woven abrasives are used in a wide range of industries, e.g. fitting and container construction, the aeronautical and gas turbine industry, tool and mould-making. They are excellent when used for deburring, cleaning or working on the surface of many metals, including aluminium, brass, copper, nickel, stainless steel (INOX) and titanium. They are also suitable for working on other hard-to-grind materials, such as ceramic, glass and plastic.

They are waterproof, washable and extremely durable. Non-woven abrasives do not clog up, do not leave rust on surfaces and are not conductive.

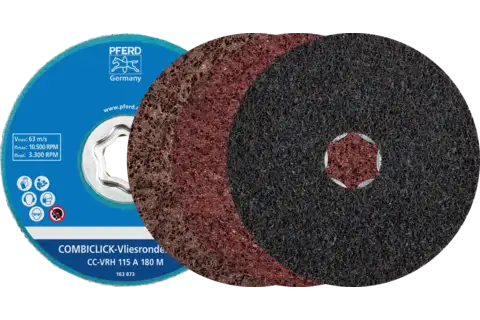

A quick explanation of PFERD designations

Other versions

Non-woven abrasive can also be manufactured with fabric reinforcement. The non-woven abrasive material is provided with much higher levels of aggressiveness and stability. Non-woven abrasive with fabric reinforcement is suitable for manufacturing discs, wheels and non-woven belts.